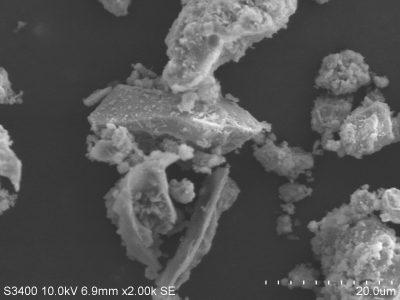

Scanning Electron Microscopy (SEM) with EDX Analysis

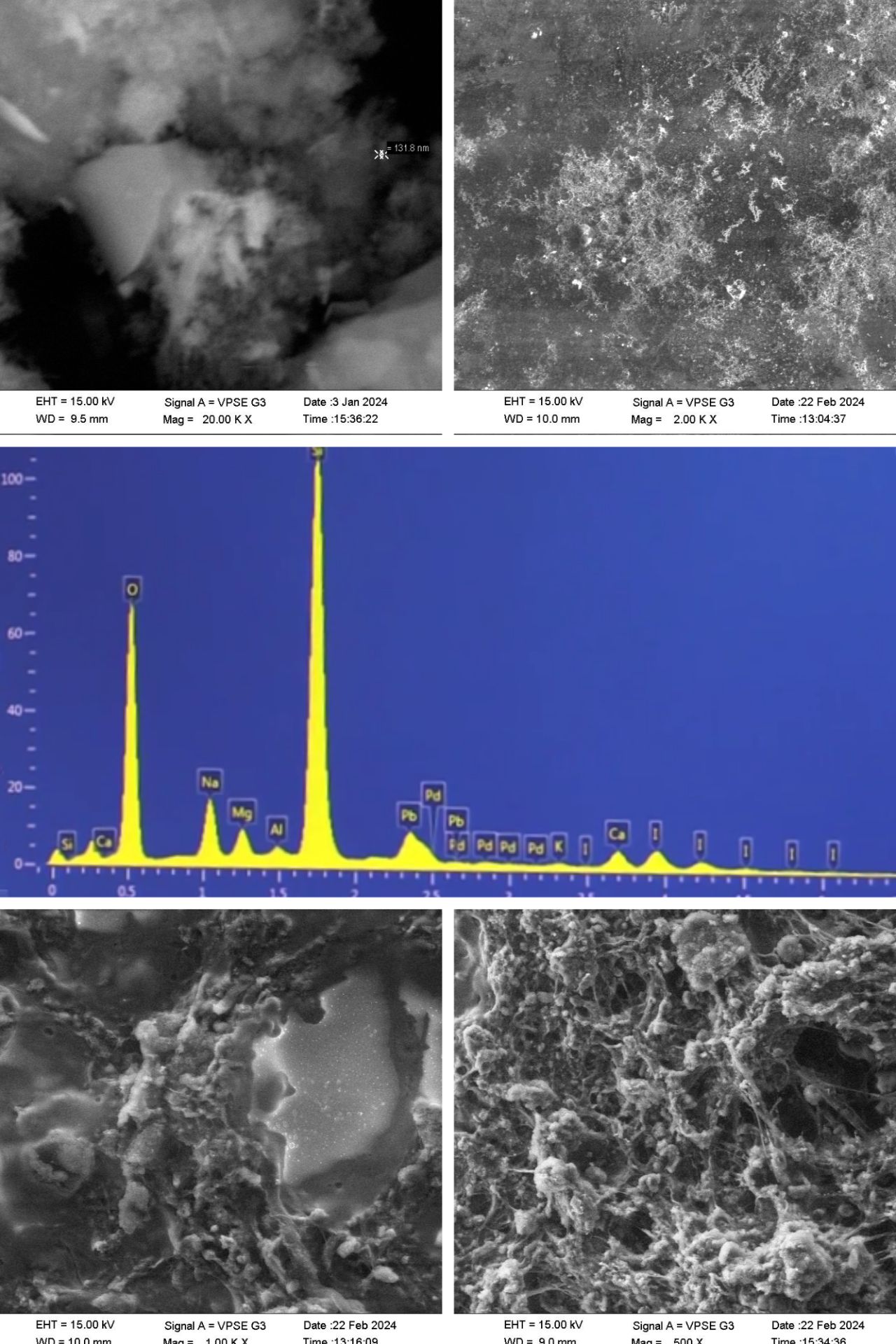

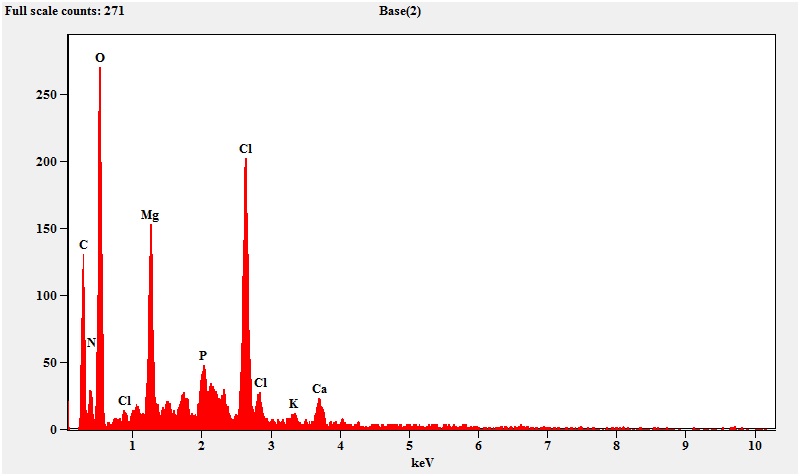

Scanning electron microscopy (SEM) with energy-dispersive X-ray spectroscopy (EDS or EDX) generates a sharp picture of the sample’s microscopic surface structures and provides information about its elemental composition. SEM-EDX analysis is suitable for almost all sample types and has a vast number of applications from basic scientific research to product development and quality control.

What is SEM-EDX used for?

SEM-EDX has many applications in industrial manufacturing and materials science. It can also be used for energy and resource management, as well as for the examination of consumer-packaged articles. With SEM-EDX, large, heavy, and challenging samples can be examined with excellent image quality showing the smallest details and the chemical composition of the material’s surface.

In product development, SEM-EDX is commonly used for failure and defect analyses and process characterization. Particle type and size determination and material classification can also be performed with the help of SEM-EDX to ensure the quality of the product and optimize its production processes. It is also possible to perform reverse engineering and breaking mechanism analyses.

Elemental mapping, where different elements and compounds detected by the EDX detector are marked with different colors in the picture, is an effective method for observing the elemental composition of a sample at a glance. SEM-EDX can also help determine if the produced material has some additional substances, and at which point of the manufacturing process they have ended up in it.

Deeper structural analysis of different materials, including the examination of surface topology, detection of surface contamination as well as determination of the causes of chemical reactions, such as corrosion and oxidation with the help of SEM-EDX can also be very useful for research and development work.

How does SEM-EDX work?

With SEM, the microscopic surface structures of the sample can be observed with high precision. A scanning electron microscope typically has a resolution in the nanometer range, which is much higher than that of a traditional light microscope.

Therefore, a more accurate image of the sample’s surface topography is obtained with SEM. More information about the SEM operating principle can be found on our SEM page.

A large selection of needs in science and industry can be met with SEM, as many different accessories can be added to the microscope to get different kinds of information about the sample (e.g. EBSD, BSE).

When the goal is to determine the elemental composition of the sample, an additional EDX detector is attached to the SEM machine. The EDX detector identifies the elements in the sample along with determining their concentrations and distribution.

For more information about our SEM analysis capabilities or to request a quote, Please mail us at [email protected]