Tamilnadu Test House offers thermal analysis services to evaluate the effect temperature has on a materials performance. TNTH provides information on the melting point, decomposition point, changes in composition thermal transition points, including the glass transition, crystallization and melting temperatures.

DSC and TGA Testing Services

Differential Scanning Calorimetry (DSC)

DSC is a technique to provide insight into thermal transitions that do not cause a weight change. By monitoring heat flow over a time and at desired temperatures, we do characeterisation of thermal behavior of Polymer samples. Tamilnadu Test House offers the DSC for a variety of organic, polymer, mineral and metallic samples from ambient up to 1600 °C (and DTA up to 1200 °C). We provide detailed report on material’s phase changes (melting point, boiling point, fusion), heat capacity (Cp), and in the case of polymers, the glass transition temperatures (Tg). Thermal behavior of low vapour pressure liquids can also be studied at TNTH facility using low pressure closed crucible (500 bar @500Deg C).

DSC analysis will give the following

- Glass Transitions

- Melting and Boiling Points

- Crystallization time and temperature

- Percent Crystallinity

- Heats of Fusion and Reactions

- Specific Heat

- Oxidative/Thermal Stability

- Rate and Degree of Cure

- Reaction Kinetics

- Purity

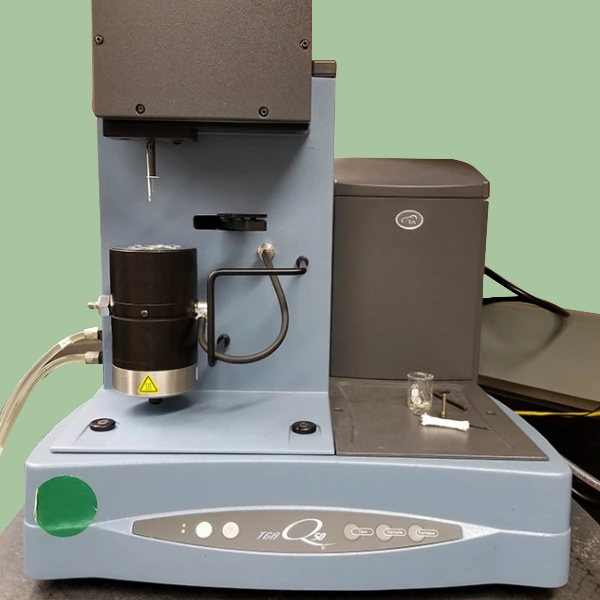

Thermogravimetric Analysis (TGA)

TGA is a technique to provide insight into changesin mass of the sample as a function of temperature, atmosphere and time. By monitoring the weight of a sample within a furnace, thermal effects that cause a weight change can be identified and studied. This is perfect for the thermal analysis of a material decomposition temperature, thermal stability, adsorption and desorption, dehydration, and combustion.

TGA analysis will give the following

- Thermal Stability

- Oxidative Stability

- Composition of Multi-component Systems

- Estimated Lifetime of a Product

- Decomposition Kinetics

- The Effect of Reactive or Corrosive Atmospheres on Materials

- Moisture and Volatiles Content

Both techniques can be applied to wide ranging types of materials from pharmaceuticals ingredients and finished products, plastics, metals, ceramics, petrochemical, and advanced materials.

Some differences and similarities between the two techniques are highlighted in the table below.

| Application | Therogravimetic analysis TGA | Differential Scanning Calorimetry DSC |

| Primary Determination | Changes in the sample mass as a function of temperature or time | Changes in the heat flow to and from the sample as a function of temperature or time |

| Temperature Range | Room temperature to 1,000°C | -170°C to 600°C |

| Heating Rate | 0.001°C/min to 200°C/min | 0.001°C/min to 500°C/min |

| Cooling Rate | N/A (not controlled) | 0.001°C/min to 500°C/min |

| Resolution | 0.1 µg | 0.25 μW |

| Analysis Environment | Inert (nitrogen flow), | Inert (nitrogen flow), |

| or oxidizing (air flow) | or oxidizing (air flow) | |

| Sample Amount | Approximately 5-50 mg | Approximately 5-50 mg |

| Typical Output | · % by mass lost or gained | · Transition temperature (e.g. onset, peak) |

| · residual mass | · Transition enthalpy | |

| Example of Applications | · Moisture content | · Phase transitions, e.g. melting (fusion), crystallization |

| · Decomposition | · Glass transition | |

| · Thermal stability | · Solid-solid transitions, e.g. polymorphism, cold crystallization | |

| · Compositional analysis | · Concentration analysis (with known standards) | |

| · Oxidation | · Specific heat | |

| · Oxidative induction time and temperature (OIT) |